Sintered Stone Slabs, Also Referred To As Large Format Porcelain Slabs, Are Manufactured Using High Temperatures And An Italian 44000-tons SUPER-TONNAGE PRESS MACHINE. Surface Veins Are Digitally Printed Using Advanced Technical Machines. They Boast Qualities Such As Stain Resistance, Extremely Hard, Scratch Resistance, Durability, And Resilience Against Heat And Frost.

Available In Large Formats Of 3200x1600mm And 2400x1600mm, These Slabs Ensure Seamless Surfaces. it Is Ideal For Modern Kitchen And Bathroom Applications Including Worktops, Countertops, Vanity Tops, Backsplashes, Shower Walls, Flooring, And Wall Facades, Sintered Stone(Large Format Porcelain) Slabs Are Increasingly Recommended By Designers’ As Next Generation Of Countertop Materials.

What Is Sintered Stone

Sintered Stone is a new type of porcelain material made from natural raw materials through a special process, also known as “large porcelain”.

(References: Caesarstone Porcelain Countertops Collection)

The relationship between sintered stone slabs and ceramic tiles is also worth discussing. Although sintered stone slabs are similar to ceramic tiles in appearance, texture, and usage scenarios, they are not another name for ceramic tiles, but a new type of building material with a natural rock texture.

In addition, the characteristics of sintered stone slabs also include high hardness and wear resistance, which makes it widely used in construction, floors, walls, roofs, etc. It is also fireproof and waterproof, suitable for a variety of indoor spaces, and become a unique choice in home decoration. Due to its unique texture and color, each sintered stone slab has its unique charm, meeting people’s demand for personalized decoration.

In general, sintered stones are a new type of material that combines beauty and practicality. Its appearance not only enriches the choice of building materials, but also provides more possibilities for designers and consumers.

What Sintered Stone Is Used For?

- Kitchen Countertops And Island

- Bathroom Countertops

- Wall Panels

- Floors

- Outdoor Walls Or Floors

- Dinner Tables, Restaurant Tables

Sintered Stone Applications Examples

Sintered stone can be installed on nearly any surface that requires durable, large-format materials, it is one of the best stones for your consideration.

Advantages And Features Of Sintered Stone Slabs

- Smooth And Beautiful Appearance That Only High-End Quartz Stone Can Match

- Synthetic

- Ultra Hardness And Density

- Different Thickness From 3mm, 6mm, 9mm, 12mm, 15mm, 20mm

- No Porous

- Luxury Atmosphere Create

- Zero Water Absorption

- Large Format 320x160cm (126×63 inch)

- Veins Continuous

- Full-Body Patterns Option

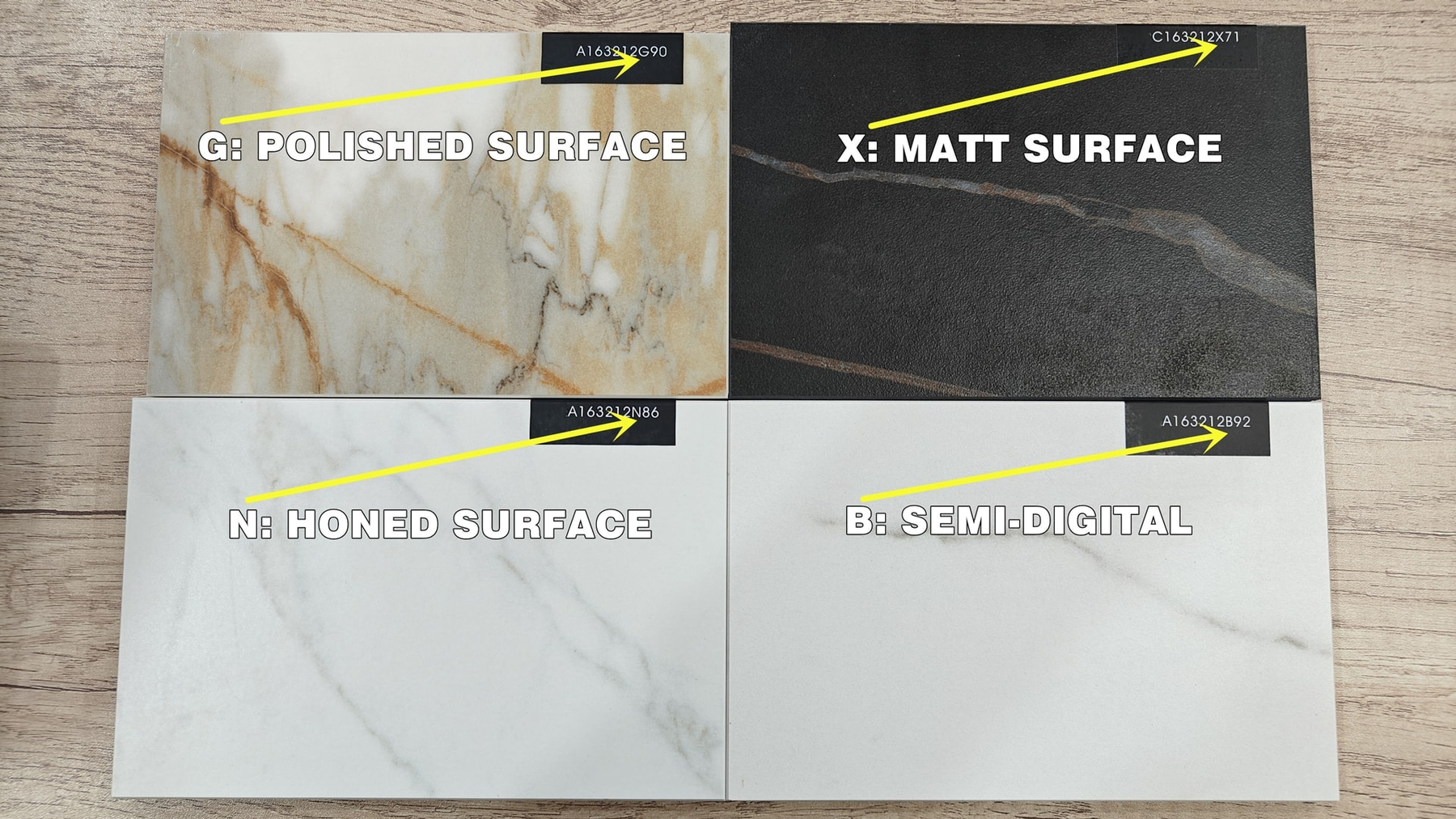

- Various Surface Treatment(Polished, Matt, Honed, Semi-Digital)

How Sintered Stone Slabs Are Made?

The production process of sintered stone slab involves the use of natural raw materials, such as natural stone powder, feldspar, quartz, clay, kaolin, etc., which are pressed by a press of more than 10,000 tons and fired at a high temperature of more than 1200℃. This material can withstand cutting, drilling, grinding, and other processing processes, has super large specifications, and is widely used in the field of home and kitchen panels. Compared with other home products, sintered stone slabs have large specifications, strong plasticity, various colors, high-temperature resistance, wear resistance, anti-penetration, acid and alkali resistance, zero formaldehyde, environmental protection, and health.

Sintered Stone Originated In Italy, Nowadays, China, and Spain are the Main Sources For All Over The World.

Cost of Sintered Stone Slabs(Wholesale Price)

Wholesale price of sintered stone slab is around 25 dollars to 400 dollars per square meter, depending on different colors, patterns, sizes, thicknesses, regions, quality, brands, manufacturing equipment, technology, etc.

To compare, quartz stone slabs’ wholesale sale price is around 20 dollars to 200 dollars per square meter.

China’s sintered stone wholesale price has been brought down because of the competition, technological maturity, and completeness of the industry, and also because of the wisdom and diligence of the Chinese people.

Durability Of Sintered Stone

- Wear Resistance: The sintered stone material has good wear resistance and is not easily affected by daily friction and wear, which can effectively reduce surface wear and scratches.

- Fire and Heat Resistance: The sintered stone material has good fire resistance, is not easy to burn, and does not produce harmful gases, which can effectively increase the safety of the building.

- Chemical Corrosion Resistance: The sintered stone material that has been specially treated has a certain acid and alkali corrosion resistance, and is not easily corroded by food, medicine, beverages, and other substances.

- Weathering Resistance: The surface of the sintered stone material is smooth, not easy to accumulate dust, not easy to breed bacteria, and not affected by weathering of age, and can maintain beauty and novelty for a long time. In addition, the rock slab material also has the advantages of UV resistance, pollution resistance, and non-radioactivity.

- UV Rays Resistance: The sun’s UV rays will not fade sintered stone

The impact resistance is the main weakness of Sintered stone, like porcelain, the Sintered stone will crack when being smashed with a hard object, but if it is installed properly or have a solid support, this weakness can be avoided.

Compare: Sintered Stone vs. Other Stone Materials

Sintered Stone is not a natural product, it’s artificial made by man, Another most used artificial stone is Quartz Stone.

Sintered Stone vs. Quartz Stone

- Similar: Artificial Stone Made By Man, long-lasting, low-maintenance, resistant to scratches and stains, antibacterial, hygienic, heat-resistant, and available in a variety of contemporary colors and designs.

- Different: Quartz Stone’s Main Components are Natural Quartz And Resin, Sintered Stone Doesn’t Include Resins; Quartz Stone is Much Better Resistant To Impact and Crack, While Sintered Stone Will Break Without Proper Support; Sintered Stone Can Withstand High-Temperature up to 1000 Celsius, While Quartz Stone Only Around 300 Celsius, The Resin Can’t Withstand High temperatures, Hot Pan Can’t be Put On Quartz Stone Directly, While Sintered Stone is Ok; Moreover, Sintered Stone Can Be Thinner Like 3mm, 6mm, 9mm, While Thinnest Quartz Stone Is 12mm (Actually Rarely Have Clients Use 12mm Thickness Quartz Stone)

Sintered Stone vs. Natural Stone(Marble, Granite) Countertops

- Similar: Sintered Stone, Marble, And Granite Are Solid, Hard; All Real Stone Materials, Resistant To Scratching; And They Are Heavy, Need Professional Tools To Move Or Cut

- Different: Natural Stones Like Marble And Granite Are Porous, Which Has Small Holes On The Surfaces, Water Or Other Fluid Might Easily Sink To Inside, So Need To Be Sealed After Install, Sintered Stone Is Dense, No Porous, No Need To Sealed. Natural Stone Patterns Are Come From Natural, Might Difficult To Find Two Slabs With the Same Pattern, In Addiction, Sintered Stone Patterns Are Printed, More Richer In Color And Imagination, And With Bright Colors

Sintered Stone Countertop Pros and Cons

Pros:

- High-Temperature Prof

- Resistant To Sun’s UV

- Water Prof

- Environmental Friendly

- Hygiene, Direct Touch With Food Ok

- Anti-Bacteria

- Scratch Resistant

- Rich Patterns

- Smooth, Bright

- High Hardness

- Dence, No Porous

- Can Be Thinner To 3mm, 6mm, 9mm, 12mm

- Large Size 3200x1600mm

- Veins Can Be Continuous

- Rich Surface Treatment: Polished(Glossy), Matte, Honed, Semi-Digital

- Full Body Patterns Option

- Ourdoor Use Available

Cons

- May Crack Or Ship Without Proper Install

- Professional Skill Or Tools To Fabricate

- Proper Way To Move Or Transport

Large Sintered Stone Manufacturer

Cosentino Global, S.L.U Spain: https://www.cosentino.com

Ceaserstone Israel: https://www.caesarstoneus.com

Neolith Spain: https://www.neolith.com

Lapitec Italy: https://www.lapitec.com

Laminam Italy: https://www.laminam.com

IN THE END

As A New Stone Product, SINTERED STONE Has Become A Strong Competitor To Marble, Granite And Quartz Stone. Sintered Stone Is A Stone You Can Not Ignore. If You Are Looking For an Original Factory That Supplying Pricing And High-Quality Sintered Stone, Or You Want to Develop A Brand Of Your Own, Come To Us, We Are The Right Choice.

CONTACT US AT

Email: austin@linxsurfaces.com

WhatsApp: +86 180 0549 3293

USEFUL LINKS

YOUTUBE CHANNEL: LINX SURFACES CHINA

WIKI: Sintered Stone Linx “Wikipedia”

Your words possess both the lightness of a feather and the weight of wisdom — a rare and beautiful balance.