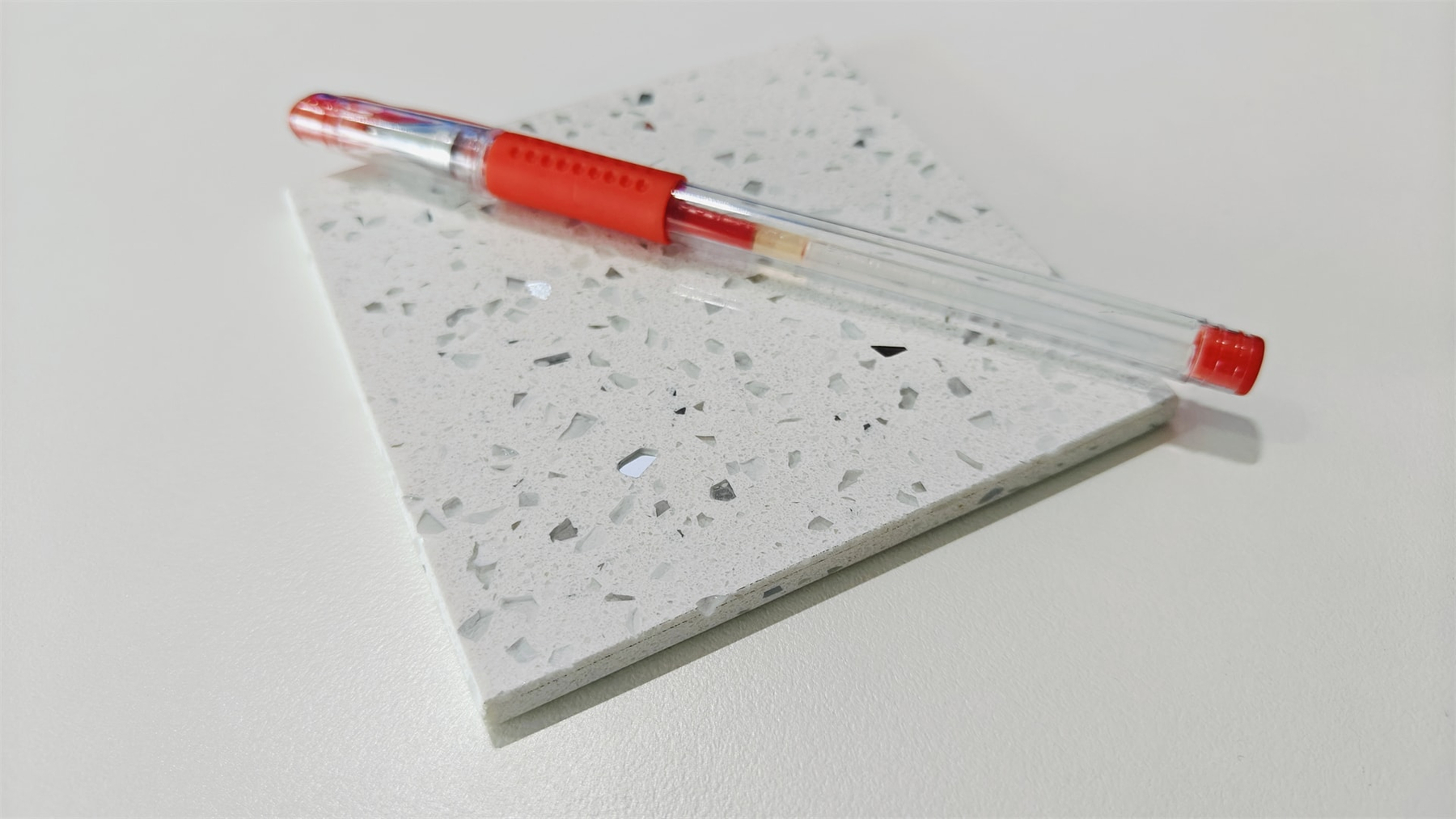

Artificial stone is a decorative material artificially manufactured from natural stone powder, stone granules, or other inorganic mineral materials with binders such as organic resin or cement, through processes such as vacuum, high pressure, vibration, and curing. It resembles natural stone in appearance but has optimized properties, exhibiting greater stability and plasticity.

1.1 Definition and Classification of Artificial Stone

Artificial stone, also known as engineered stone or synthetic stone, refers to a man-made material produced by mixing natural stone particles (such as quartz, marble, or granite powder) with binding agents like resin or cement. Through a series of industrial processes including vacuum pressing, vibration, high-temperature curing, and surface polishing, artificial stone achieves a natural stone-like appearance with enhanced physical and chemical properties.

Main classifications of artificial stone include:

- Artificial Marble – Made primarily from calcium carbonate or marble powder with polyester resin as the binder. It has elegant colors and patterns, suitable for interior decoration.

- Artificial Quartz Stone (Engineered Quartz) – Contains more than 90% natural quartz crystals, combined with resin and pigments. It is known for its hardness, durability, and chemical resistance.

- Solid Surface / Acrylic Stone – Produced using aluminum hydroxide and acrylic resin. It is seamless, thermally formable, and ideal for complex designs and custom shapes.

- Cement-based Artificial Stone – Made from cement, sand, and pigments, typically used for exterior wall panels, garden paving, and architectural decoration.

1.1.2 Product Characteristics of Artificial Stone

Artificial stone is designed to combine the aesthetic appeal of natural stone with the performance advantages of modern materials. Its main characteristics are as follows:

- Rich and Consistent Appearance – Available in a wide range of colors and textures, with uniform patterns that can imitate marble, granite, or creative designs beyond natural stone.

- High Strength and Durability – Quartz-based artificial stone reaches a Mohs hardness of 7 or higher, providing excellent resistance to scratching and abrasion.

- Low Water Absorption and Stain Resistance – The dense structure prevents liquid penetration, making it easy to clean and maintain.

- Chemical and Heat Resistance – Resistant to acids, alkalis, and common household chemicals; suitable for kitchens and laboratories.

- Eco-friendly and Non-radioactive – Free of natural radioactive substances, safer for residential and commercial environments.

- Easy Fabrication and Installation – Can be cut, drilled, and polished with standard stone-processing equipment; allows for seamless joints and diverse applications.

- Stable Performance – Resistant to fading, cracking, and deformation under normal indoor conditions.

1.1.3 Applications of Artificial Stone

Due to its versatility and durability, artificial stone is widely used in both residential and commercial projects, including:

- Kitchen Countertops and Backsplashes

- Bathroom Vanity Tops and Washbasins

- Wall and Floor Cladding

- Stair Steps, Window Sills, and Door Frames

- Reception Desks, Dining Tables, and Furniture Tops

- Hotel, Hospital, and Shopping Mall Interior Decoration

- Laboratory and Cleanroom Work Surfaces

Its combination of aesthetic value, strength, and hygiene makes it one of the most preferred materials for modern interior design and architectural applications.