Stone Slab Clamp 1T

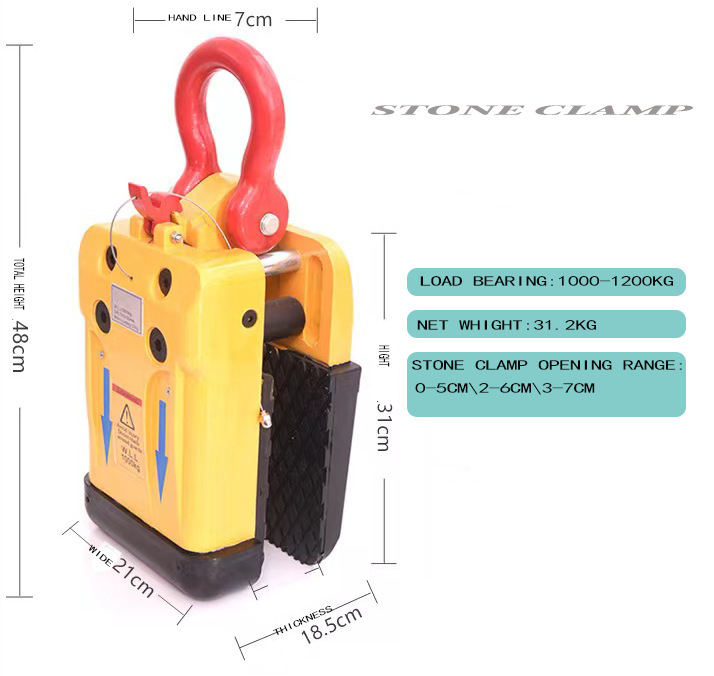

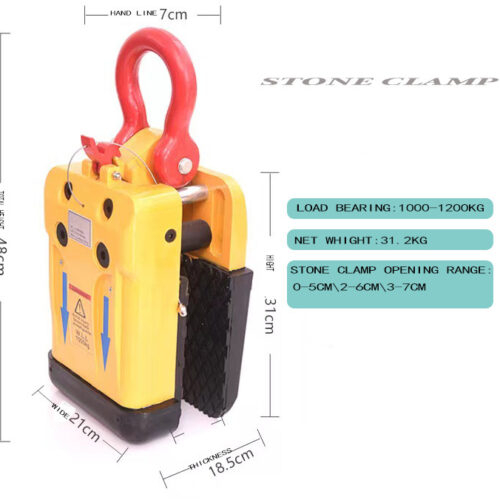

| NAME: | Stone Clamp |

| OPEN: | 0-50MM |

| LOAD CAPACITY: | 1000KG |

| NET WEIGHT: | 31.2KG |

| PACK SIZE | 26x26x42CM |

| APPLICATION | QUARTZ STONE, SINTERED STONE, MARBLE, GRANITE STONE SLAB |

$286.00

Lifting clamps slate clamps marble granite artificial quartz slab slate clamps load-bearing 1 ton

Note:

When lifting or moving slabs with a forklift or other mobile equipment, we recommend that you only operate on a stable, level surface, avoiding potholes or rough surfaces. Vibrations from forklifts and lifts may cause the clamps to loosen or damage the clamps and forklifts.

1. When performing lifting operations, carefully consider all safety regulations and current regulatory specifications in the country where you are located.

2. Only personnel who have been trained, have the ability to operate, and are familiar with the operating instructions and safety regulations are allowed to operate.

3. Check the clamps. If the clamps are worn or damaged, they cannot be used.

4. Choose the right size clamp for the job. Determine the weight of the sheet to be lifted. Do not exceed the working load limit marked on the clamp. The thickness of the sheet must be within the range specified by the manufacturer.

5. Keep everyone away from the clamps that are being lifted or moved.

6. Grip depends on friction. Check that the rubber pads are free of dirt, grease and other things that may reduce the effect.

7. Do not lift wet sheets. Grip depends on friction. Lifting wet sheets may cause the rubber pads to lose grip.

8. Do not lift more than one sheet at any time.

9. Clamp the sheet in the center to maintain balance when loading.

10. Make sure the sheet is fully clamped in the clamp during operation.

11. Lift the sheet slowly. Check the lifting tension to achieve proper balance.

12. When lowering the sheet to the rack, do not lower the clamp to other sheets or materials, otherwise the clamp will release its load.

13. Before lifting any product, the hook should be checked for wear and tear. If worn, it should be replaced. When the product is clamped to the clamp with a hook, the rotation of the product will cause the hook to be easily damaged.

b. Basic safety instructions for lifting accessories

Important! To avoid personal injury, follow the following basic safety instructions when using lifting accessories.

1) Make sure the operating manual is placed within the visible range of the lifting accessories.

2) Lifting accessories are only allowed to be used by professionally trained and skilled personnel.

3) Wear safety equipment such as helmets, gloves and safety boots.

4) Never lift without supervision.

5) Ensure that the clamp is used in a safe and orderly working environment.

6) The lifting weight is limited to the weight to be loaded.

7) Do not be below during lifting, and do not allow others to enter.

8) Never let the accessories loose when connecting or lifting them separately.

9) The lifting accessories must be stored in a place that is moisture-proof and corrosion-proof.

10) Defective lifting accessories cannot be used again.

11) Repairs and inspections should be performed by professionals.

12) Avoid rotation during lifting. If rotation is necessary, it is necessary to check whether the hook is safe because the hook is a fragile item.

Instructions For Use

Preliminary installation inspection

Before using the stone clamp, the specialist must check the following:

* Make sure that the stone clamp is used in a safe and orderly working environment.

* Make sure that the swivel hook is correctly installed and fixed to the stone clamp

* All locating pins on the forklift are accurately positioned and fixed in a safe and orderly manner.

1) Move the top sheet to the packing board using the pry bar and wedges, allowing enough space for the support plate of the clamp to pass through the sheet and the packing board. Do not move the top sheet through the balance board, keep it in an inclined position.

2) Place the clamp flat on the center of the sheet so that the load is stable.

3) Make sure that the sheet is deeply clamped in the open clamp.

4) Unlock the latch so that the clamp will lock on the sheet when the crane cable is raised.

5) Lift the sheet slowly to ensure that the load is balanced.

6) When lowering the hoist, make sure there are no obstacles blocking the descent to ensure that the clamp can be removed after the hoist.

Cum sociis natoque penatibus

Purus in mollis nunc sed id semper risus. Velit laoreet id donec ultrices. Tellus pellentesque eu tincidunt tortor. Cum sociis natoque penatibus et. Vitae elementum curabitur vitae nunc sed velit. Nulla pellentesque dignissim enim sit amet venenatis urna cursus eget.

Mattis enim ut tellus elementum

Dolor morbi non arcu risus quis. Quisque non tellus orci ac auctor augue mauris augue. Ipsum a arcu cursus vitae congue mauris rhoncus aenean.

- Cum sociis natoque penatibus et

- Aliquam eleifend mi in nulla posuere

- Ullamcorper malesuada proin libero

- Purus in mollis nunc sed id

Reviews

There are no reviews yet.